How is laundry detergent filled and how does the filling machine work?

Oct 14, 2024In our daily life, washing clothes is a daily routine for individuals and families. When we need to wash clothes, we often need to use laundry detergent. Therefore, laundry detergent plays an indispensable role in our lives. The filling of laundry detergent requires the filling equipment of the packaging industry to be packaged so that it can be sold conveniently. This article will introduce you to how liquid pastes are filled into various containers. These equipment are not only highly efficient but also can ensure the accuracy and consistency of packaging. Next, I will give you a detailed introduction to how liquid detergents are filled, from their composition to the operation process and the benefits of these equipment.

Composition of liquid filling machine

To understand how laundry detergent is filled, you need to have an understanding of the components of the machine. The operation mode of these components has a profound impact on the filling of the machine. It is mainly composed of the following components:

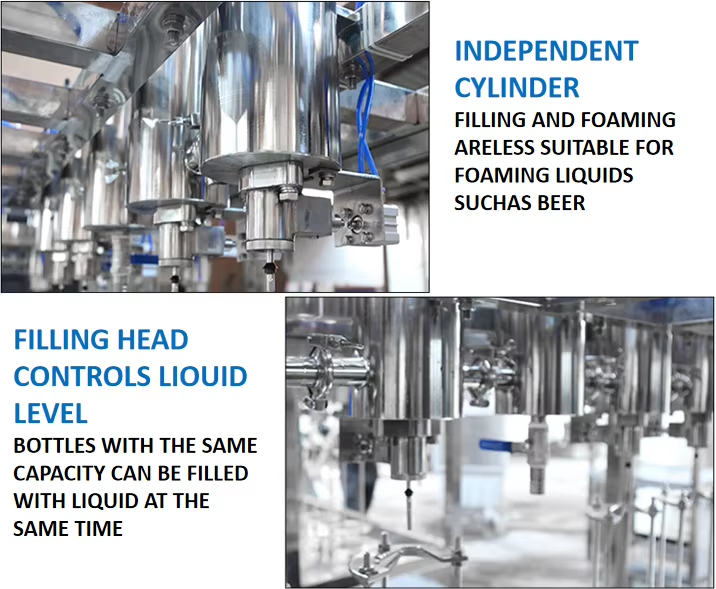

1. Filling head:

The function of the filling head is to fill the required liquid into the allocated container. The number of filling heads depends on your production needs for the machine and the capacity of the machine. The automatic liquid filling machine needs to distribute the materials to be filled through the filling head.

2. Conveying system:

The conveying system needs to deliver the containers waiting to be filled to the filling station, and send them to the capping station and sealing station respectively through the conveyor belt. Ensure that the filled containers can flow on the production line.

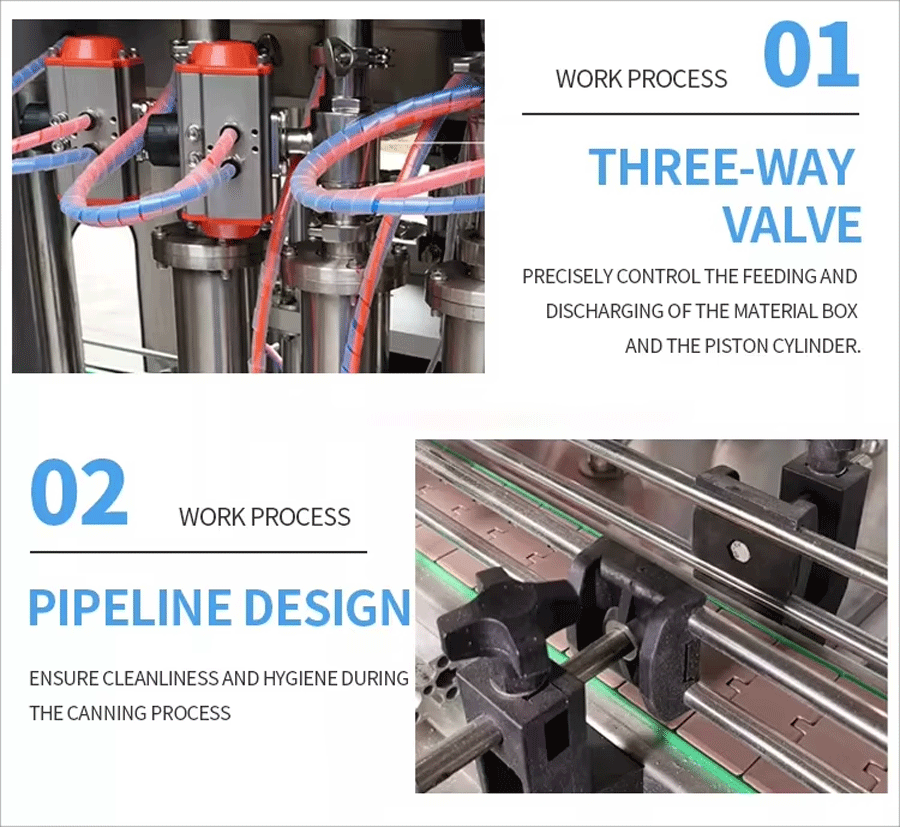

3. Pump system:

The water pump needs to transport the detergent from the storage tank to the filling head by extracting it. Generally, different pumps can be used according to the viscosity of different detergents. This depends on your material. You can choose piston pumps, peristaltic pumps or gear pumps.

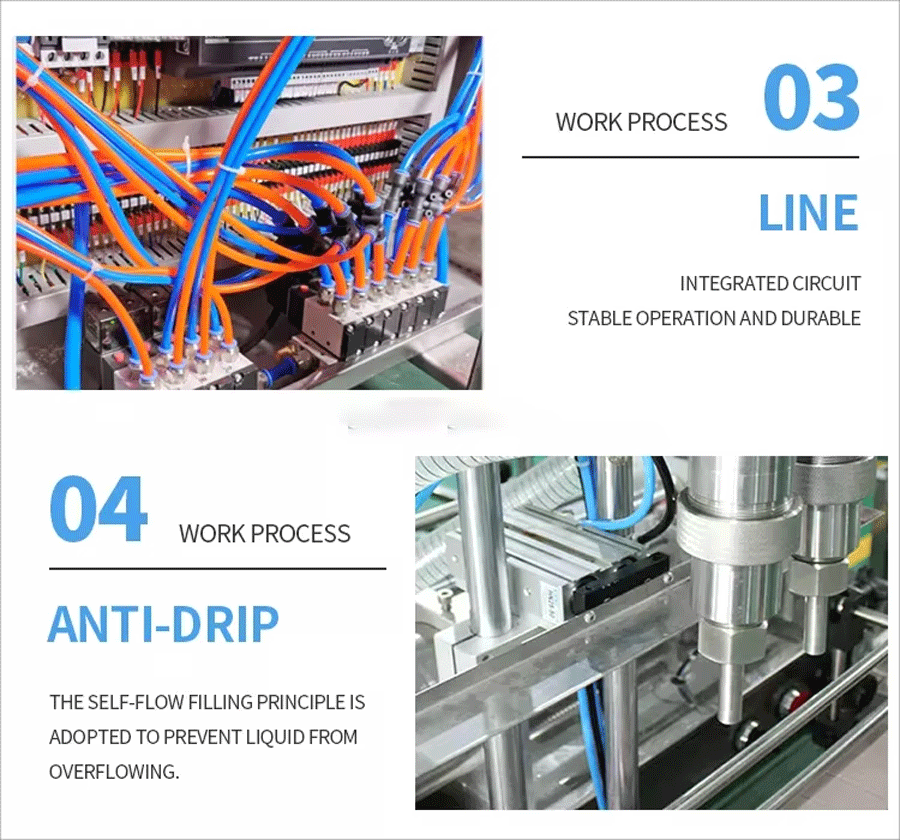

4. PLC control system:

Because of the development of the packaging industry, filling machines are now equipped with very advanced control systems. The use of programmable logic controllers (PLC) and touch screens makes the operation easier to understand. Operators only need to set parameters for filling speed, filling capacity and other operations. With such a simple and clear operation page, operators only need simple training to use the machine.

5. Sensors and actuators:

Sensors and actuators are essential parts of the machine. Sensors play a key role in checking the presence of containers and whether the containers are placed in the right position. The actuator controls the opening and closing of the filling valve and other mechanical movements, and cooperates with other parts of the machine to form a complete production line.

Working steps of laundry detergent filling machine

The work of the filling machine requires the cooperation of different parts to form a complete working line. The filling and precision of the machine are achieved through the mutual cooperation and collaboration of each part.

(1) Container arrangement

The container bottles waiting for filling enter the conveying system through manual or automatic conveyor belts. They are arranged to wait for filling. This requires ensuring the correct spacing between containers to ensure the accuracy of filling and reduce the error rate of production. Therefore, this is particularly important.

(2) Positioning and detection

Each machine is equipped with a sensor to sense the distance of the container. The positioning of the container is carried out by detecting the container to ensure that the container can accurately stay under the filling head.

(3) Filling

When the container stops at a fixed position, the pump system will extract the packaged laundry detergent from the storage tank container and distribute it to the container through the filling head according to the set weight. The filling weight and speed are controlled by the machine control system, which plays an important role in accurate weight control and reducing overflow.

(4) Capping and sealing

This is the last step of the filling machine. When the container is full, the capping and sealing will be performed to seal the packaged material and prevent leakage. In this way, the operation of the filling machine is basically completed.

Types of filling machines

Filling machines have many different models, and different machines correspond to different production requirements. Some common filling machines are

(1) Pneumatic filling machine

It refers to the machine that needs to be connected to an air compressor to drive the machine through compressed air. It is more suitable for fast filling production lines.

(2) Piston filling machine

This is to achieve the purpose of extracting and removing liquids through the movement of the piston. It is suitable for filling materials with relatively viscous materials, such as ketchup, honey, shampoo, etc.

(3) Gravity filling machine

The liquid enters the container through gravity. It is more suitable for liquids with lower concentrations, such as water, juice, etc.

Benefits of using a filling machine

1.Improve efficiency

The filling machine integrates filling, capping and sealing into one machine, which can significantly improve production efficiency and speed up the filling process for you to achieve high-quality and high-speed output in a short time.

2. Accurate filling

It can ensure that the filling capacity of each container is consistent, so that you can accurately control the production cost without causing waste.

3. Cost saving

The use of the machine can reduce the labor cost and time cost, improve your production efficiency and reduce waste to achieve the purpose of reducing costs for you.

4. Flexible use

The filling machine can fill containers of various sizes and shapes for you, without disassembly and assembly to adapt to your diverse packaging effects.

Through the above introduction, the laundry detergent filling machine is a high-efficiency and high-precision packaging machine. By showing you the components, operation process, and benefits of the machine, it can help you understand the machine and make a wise choice. Incorporating the filling machine into your production plan is a perfect solution to provide you with more efficient, accurate, and high-quality packaging products.